The Lighthouse was opened in 1873, and is a rare example of granite stones being used on the West Coast of Norway. Because of this, it has been given Norway’s highest order of listed building protection. The lighthouse also has a lot of history from the second world war, where it was modified by German troops to be a lookout, and features artwork on the basement walls painted by troops stationed there.

The Lighthouse was opened in 1873, and is a rare example of granite stones being used on the West Coast of Norway. Because of this, it has been given Norway’s highest order of listed building protection. The lighthouse also has a lot of history from the second world war, where it was modified by German troops to be a lookout, and features artwork on the basement walls painted by troops stationed there.

For many years there would have been people living in the lighthouse, burning fires in the fireplaces. Nowadays the lighthouse is automated and functions as a museum and art gallery. The lighthouse has been increasingly suffering from damp, which is damaging the building and the historic painting within.

The dampness has been attributed to:

- Inappropriate materials being applied to the building – in the form of cement pointing, and latex paints.

- The change in use of the building and no longer having proper ventilation (the chimneys have been blocked)

The Solutions to Damp

As part of a series of works to preserve the lighthouse, it was decided to:

- Remove the cement pointing and replacing with lime.

- Fix the guttering so that water did not pour onto the face of the wall.

- Lime wash over the blocks and pointing to give the building a ‘skin’ of breathable lime.

Why use Lime Wash?

To many, lime may look much like cement. It has some very key differences in how it handles moisture. Cement will trap moisture in, while lime will allow the moisture to breathe out of the building.

Many historic buildings have had cement added in efforts to protect them by well-meaning people. Cement is a harder and stronger material, but because of the way it handles moisture is largely unsuitable…. and some other reasons that I shall save for another post.

Why not use a local contractor?

The job was put out to tender, following the production of a report on the lighthouse. None of the proposals that came back were suggesting using suitable materials. Some even suggesting the use of cement.

The knowledge of how to use traditional materials seems to have largely died out in this part of Norway.

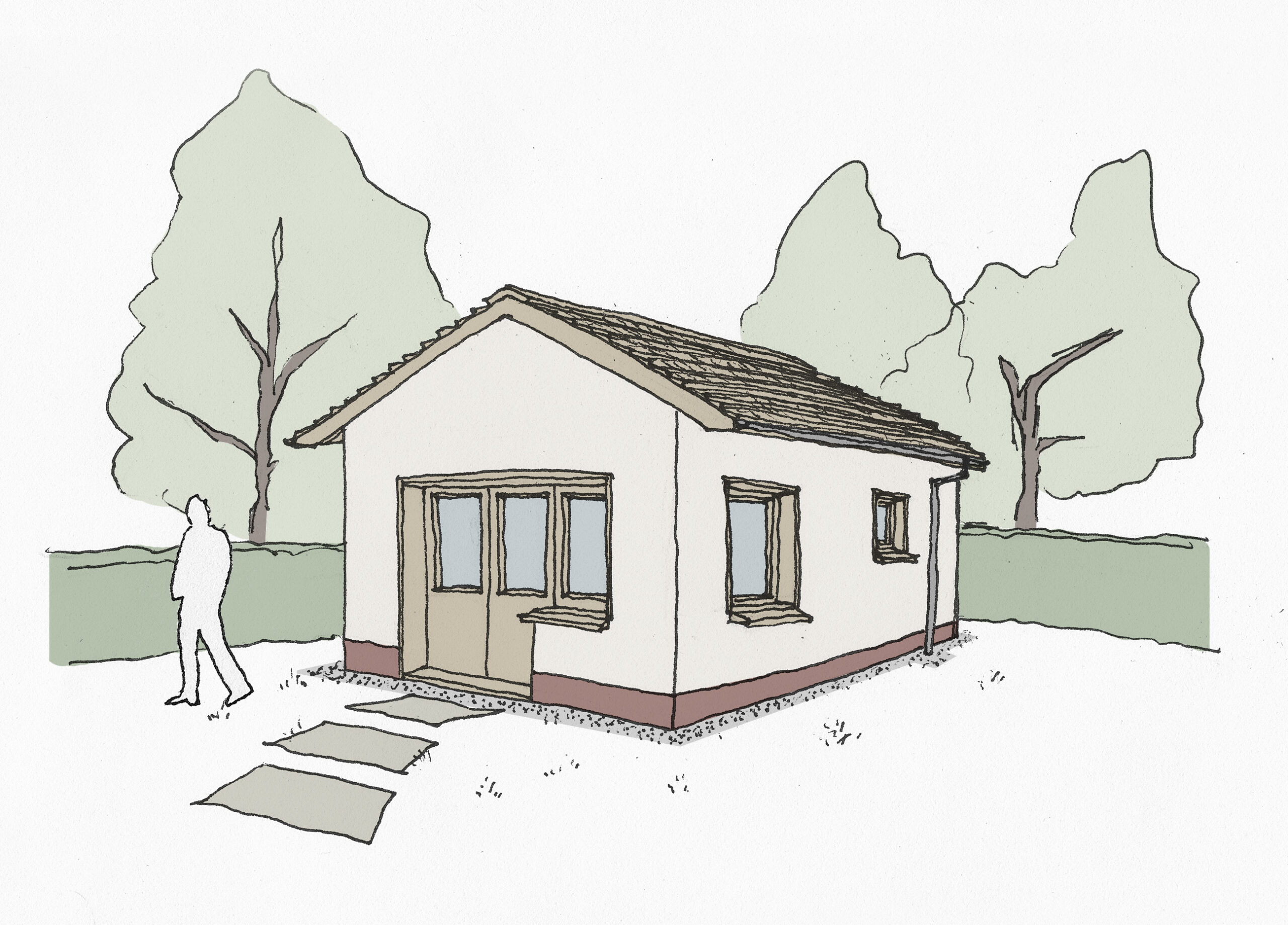

It was a joy and honour to be a small part of Ed and Rowena’s incredible journey in creating this very special home. The approach and outcome are equally wonderful.

It was a joy and honour to be a small part of Ed and Rowena’s incredible journey in creating this very special home. The approach and outcome are equally wonderful.

The Lighthouse was opened in 1873, and is a rare example of granite stones being used on the West Coast of Norway. Because of this, it has been given Norway’s highest order of listed building protection. The lighthouse also has a lot of history from the second world war, where it was modified by German troops to be a lookout, and features artwork on the basement walls painted by troops stationed there.

The Lighthouse was opened in 1873, and is a rare example of granite stones being used on the West Coast of Norway. Because of this, it has been given Norway’s highest order of listed building protection. The lighthouse also has a lot of history from the second world war, where it was modified by German troops to be a lookout, and features artwork on the basement walls painted by troops stationed there.